Technical Data

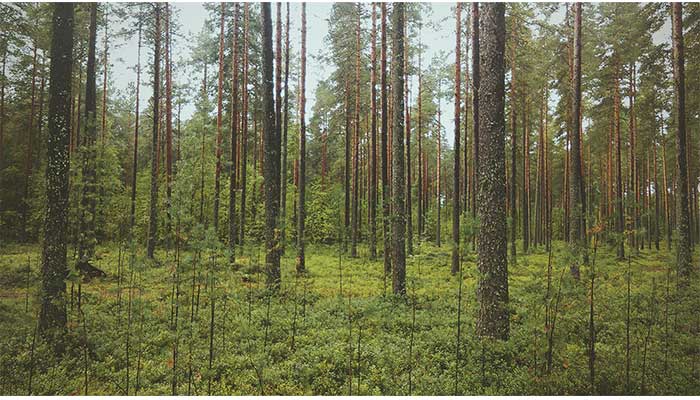

Wood as raw material

Since antiquity, timber has been a construction material and a raw material for producing a wide range of goods. Due to its many advantages and its convenience to be treated, it is still used widely in architecture and public spaces, despite the emergence of other competitive materials. Wood is known for a great

Wood is characterised by a a wide variety in colours, textures and design providing unequal aesthetics a feeling of warmth, a feeling of warmth to the touch and sight.

Wood is a very resilient and stable material and it has a high mechanical resistance compared to its weight. According to researches, construction timber is 20% more stable than steel and 4 to 5 times better than concrete. Moreover, it is a natural insulator because of the air molecules within its cellular structure. As an insulation material, wood is 15 times more effective that stone, 400 times better than steel and 1770 times better than aluminium.

Wood is a very resilient and stable material and it has a high mechanical resistance compared to its weight. According to researches, construction timber is 20% more stable than steel and 4 to 5 times better than concrete. Moreover, it is a natural insulator because of the air molecules within its cellular structure. As an insulation material, wood is 15 times more effective that stone, 400 times better than steel and 1770 times better than aluminium.

The production and use of wood can contribute to the prevention of climate change and the protection of the environment, since it is a renewable material under specified production conditions.

What types of wood are used for wooden windows?

SYLOR – Wooden Solutions wooden windows are constructed by selected, thermally processed laminated timber..

SYLOR – Wooden Solutions wooden windows are constructed by selected, thermally processed laminated timber..

Laminated wood is a natural product, which is made by the welding of an even number of solid wood layers, in a way that the grains of each layer are transverse to the other.

Laminated wood technology

Stability: The laminated technology (3 or 5 wood layers) prevents the natural distortion of wood.

Resistance: The welding process in high frequency renders the laminated timber much more resistant than solid wood.

Sustainability: The laminated wood panels are a natural product that contains no harmful or polluting materials, such as plastic, oil etc.

Available types of wood

Different types of wood can be used for the construction of wooden windows, shutters and entry doors, depending on the desirable properties, grain and tints. Our team of experts at SYLOR - Wooden Solutions can guide you through the process of choosing the right type of wood, based on your preferences and the conditions of the location, where the windows will be installed.

The available types of wood are:

Iroko

Its commercial name "IROKO" originates from Nigeria. Iroko forests flourish throughout tropical Africa from Ivory Coast to Kenya, and Eastern Africa from Congo to Benin.

Specific gravity: 750 kg/cu.m.

Its durability over time is estimated to more than 25 years, without being varnished and fully exposed to weather conditions. Iroko, even medium-hard, is a very durable type of timber and can be compared to Teak for most of its properties. This is why it is an ideal wood for wooden windows that are installed in areas with difficult weather conditions, such as Greek islands.

In transverse sections the rings of the wood are visible. The colour of sapwood varies from off-white to light yellow, while the heartwood can be golden-orange to brown. Large amounts of calcium carbonate are often found within the wood, creating darker areas, which combined with the existing yellow zones of sapwood, impart an attractive look. Iroko has high photosensitivity and changes easily colour when used in external structures.

It has good mechanical properties and average specific gravity and resistance to static flexure. It has good dimensional stability and can retain its shape even after elaboration.

It is used in boat-building, domestic flooring, windows, fireproof doors, laboratory counters, furniture, sculptures and plywood.

Okoume

Okume is an African wood found in Congo, Gabon, and Equatorial Guinea.

Specific gravity: 450 - 500 kg/cu.m.

The sapwood is white or light grey and the heartwood is light pink-brown or red-brown. Its colour changes gradually especially if exposed to sun, looking like mahogany. It is a soft and light wood with rough surface and moderate stability.

Its process is difficult because its high concentration of silicate. It is mainly used for the construction of handmade furniture, windows, plywood and more

Meranti

Meranti is a deciduous tree that grows in tropical equatorial areas, Malaysia and Indonesia. The height of the tree can reach up to 70 meters and the diameter of the trunk up to 150 cm. The durability of meranti lasts for more than 15 years, unvarnished and fully exposed to weather conditions.

Specific gravity: 500 - 550 kg/cu.m.

The sapwood is light pink, while the heartwood varies from dark brown to deep red.

It is considered as a very stable timber, since after being processed its dimension does not change. Due to its medium density and hardness the timber can be worked easily with machine or hand tools. It has good mechanical properties and satisfactory quality. It has good resistance to static flexure and does not stain easily.

The fact that it is easily processed is the main reason for its wide use in construction such as flooring, furniture, plywood and veneer sheets, while its main use in Greece is as raw material for wooden windows.

Pine

Pine comes from the countries of North Europe and especially Sweden, Finland, Russia. It is a resinous wood widely available in a vast variety of types and qualities.

Specific gravity: 450 - 500 kg/cu.m.

The sapwood and the heartwood have yellow-white to pinkish colour.

It is a softwood, has good stability and is easily dried. It is worked easily both with machine and hand tools. It has a good resistance to static flexure and good mechanical properties. Its resistance depends on the amount of knots and other natural defects.

Uses of pine include furniture, wooden frames, roofs, floors, ceilings and decorative items, pergolas, verandas, and wooden houses.

Sapelli

Sapelli is an African tropical wood, which grows mainly in Central Africa

Specific gravity: 480 - 620 kg/cu.m

The sapwood is gray-pink or cream, and the heartwood is dark red-brown.

It is a hardwood, of moderate stability and it has a high mechanical strength. It is very resistant to moisture.

Sapelli is mainly used in boat-building, interior furniture, veneers and wooden windows.

European oak

European oak is one of the most common woods used as a raw material for plenty of constructions, around the world. It grows in Europe, Great Britain, Asia Minor and North Africa.

Specific gravity: 670 - 720 kg/cu.m.

Oak is a heavy and hard wood. It is usually selected because of its very special texture and the beautiful shades of its grain. The heartwood’s colour is light yellow-brown to yellow-gray, with dark characteristic grains. Its grains are usually straight and long, but they may have an irregular structure, depending on the growing conditions.

The heartwood is durable and has a medium resistance to bending and compression. It is a difficult wood to process and cut, while it behaves very well during the finishing process.

It is widely used in interior furniture making, such as kitchen and wardrobes, floors, veneers. Other uses include boat building, docking, high quality interior doors, and windows.

Due to contraction and expansion, oak is not recommended to be exposed to humidity and intense temperature changes. Therefore, it is an ideal wood for wood-aluminum profiles.

Other types of wood

Special types of wood may be applied on demand. The wood-aluminium profiles (COVER LEGNO, INCANTO) can be made of several types of wood, even more sensitive to humidity, such as ash and chestnut, thanks to the external aluminium cover.

Okoume marine plywood

Marine plywood is a special category of plywood, which has excellent resistance to humidity. It is made by gluing many and thin sheets of tropical wood using anhydrous glue. African okoume wood is widely used as a raw material for plywood.

In addition, plywood is a material with high mechanical strength and relatively light weight.

Okoume marine plywood has a wide range of applications in construction, transport, packaging, furniture, windows. It has been widely used for the construction of wooden shutters in the Greek islands.

Flat or raised panels in windows and shutters, as well as shutters in plywood, are constructed by marine plywood in okoume hardwood.

Wooden windows finishing

Wooden windows finishing is considered as one of the most important quality factors of wooden windows. The finishing determines both their ability to last in time, as well as the final aesthetic touch of wooden windows.

SYLOR – Wooden Solutions is among the very few companies in the Greek wooden window market to provide wooden windows that are painted with electrostatic coating by painting robots in specially designed plants.

Electrostatic coating

Electrostatic coating (e-coating) is a manufacturing process that employs charged particles to more efficiently paint a workpiece. Paint, in the form of powdered particles, is electrostatically charged and then sprayed towards a conductive workpiece oppositely charged. After the spraying, the windows enter a polymerization oven at 180-200 degrees Celsius (workpiece temperature) for 20-30 minutes. E-coating ensures high quality and paint adherence by the wood, homogeneity of coating even at the most hidden surfaces of the windows and last in time.

Electrostatic coating ensures

- high quality and paint adherence by the wood

- homogeneity of coating even at the most hidden surfaces of the windows

- resistance to bumps and last in time

Electrostatic coating is applied to the following profiles: Tutto Legno, Cover Legno, Incanto.

Check out all the available profiles

Eco-friendly varnishes

SYLOR - Wooden Solutions uses water-based varnishes especially crafted for the Mediterranean climate: heat and humidity, severe sunshine and high temperature variations within the day. Colours contain iron oxide pigments, that filter the ultraviolet rays of the sun, thus protecting the wood and prolonging windows’ life expectancy.

Painting process

The painting process of wooden windows is the result of years of research and responds to the weather conditions in Greece. It consists of the following stages:

- Impregnation

- Sanding

- Primer coating

- Finish in varnish or lacquer – film 175 micron thick

- Sanding

- Finish in varnish or lacquer – film 175 micron thick

- Quality control

Available colours

IROKO

OKOUME

MERANTI

PINE

PINE - DECAPÉ TECHNIQUE

Glazing

Glazing is one of the most important factors in achieving thermal and acoustical comfort and security inside the home or work environment.

The glazing type that comes with SYLOR’s standard window profiles (Softline, Tutto legno) is double, low emissions (low-e) and offer satisfactory levels of thermal insulation and sound insulation (Ug = 1,1 W/m2K, Rw = 35 dB).

Modern advances in the manufacture of glass panes provide the possibility for even more improved yields in thermal and acoustic isolation, protection against burglaries, reduction of incoming solar radiation, and so on.

Glazing can be summarized in the following three basic types:

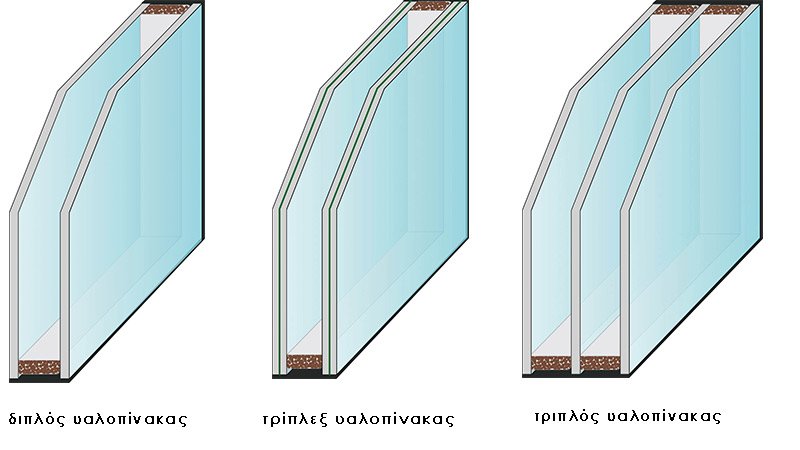

- Double glazing: Double glazing consists of two glass panes, which are placed together usually in a distance of 16mm from each other and joined through an aluminium spacer or a polyamide spacer and sealed with special glue. They provide significantly higher thermal and sound insulation, because the air between the two glass panes acts as insulation.

- Triple glazing: Respective to double glazing, triple glazing consists of three glass panes. The additional air gap offers even higher thermal and sound insulation.

- Laminated glazing: The laminated glazing consists of two (or more) layers of glass held together with one or more plastic interlayers between them, usually PVB. Laminated glazing can be placed as one of the panes in a double or triple glazing.

Based on the above standard structures, several different compositions can be created so that the glass, and therefore the window, responds to certain quality specifications. For example, the gap may be filled with noble gas with thermal insulation properties instead of air, one or more glass panes may be low-e glasses, or the interlayer in the laminated glazing may have soundproofing properties.

-

Glazing for thermal insulation

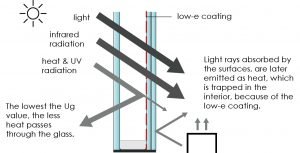

Low-e glass pane

What it is

Low emission glass panes, carry one or more glasses with an ultra thin, transparent coating comprised of metal oxides. This coating allows shortwave solar energy (visible light) to pass, but reflects much of the ultraviolet and long-wave infrared energy (heat). Low-e glazing has significantly lower emissions and increased thermal insulation capacity than normal glass. Depending on the thermal insulation performance that one wants to reach, double or triple glazing may be applied, with low-e coating on 2 glass panes.

How it is measured

Thermal transmittance coefficient (U value): The thermal coefficient is a measure of heat loss that occurs through a given glass pane. In its most basic interpretation, a low U value designates efficient thermal insulation. Low-e glazing and the use of noble gases in the glazing can significantly reduce the U value, that can reach down to 0,5 W/m2K.

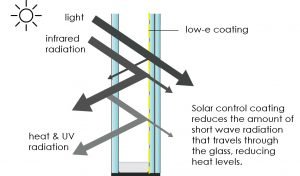

Solar control glazing

What it is

Solar control glazing has an invisible coating of metal oxides, which creates a sun protection filter. Thanks to this coating, solar control glazing prevents both long-wave (heat), and short wave solar radiation (visible light). Therefore, solar control glazing has the ability to prevent temperature rising inside the building, even when the sun ray’s directly hit the glazing.

How it is measured

Solar Heat Gain Coefficient (SHGC) and Light Transmission (LT): The Solar Factor (SF) or Solar Heat Gain Coefficient (SHGC) measures the ability of the glass to transmit solar energy into a room. It is the fraction of the solar ration that enters a building compared to the total incident solar radiation. The light transmission refers to the percentage of the visible light that passes through the glass compared to the total incident.

-

Glazing for sound insulation

Acoustic laminated safety glass

What it is

Acoustic glass consists of a minimum of two sheets of glass bonded together by at least one interlayer, known as a PVB (Polyvinyl Butyral), which absorbs part of the sound, providing protection against noise sources. The interlayer has the safety and security properties of the standard laminated glass. Acoustic glass is mostly recommended for buildings next to highways, railroads and airports. By applying more than one interlayer, the sound proofing properties increase.

How it is measured

Sound reduction coefficient (Rw): Rw is a single figure rating for the sound insulation of building elements. It is measured in decibel (dB). It includes a weighting for the human ear and measures actual sound transmittance

-

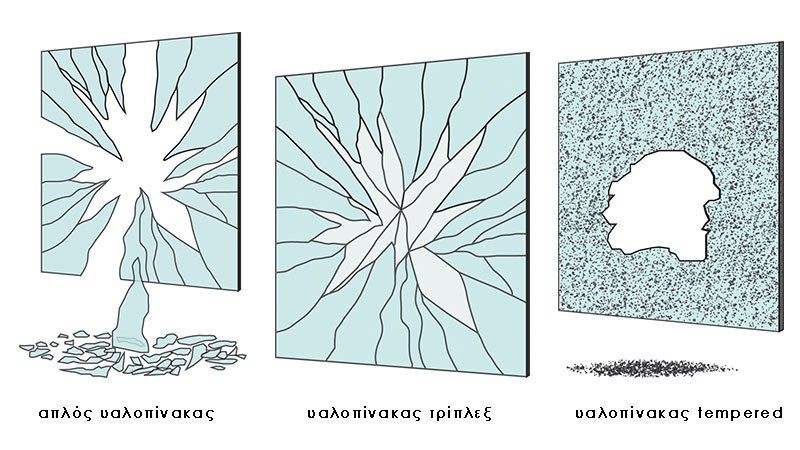

Glazing for safety

Ενώ οι απλοί υαλοπίνακες όταν σπάσουν, διαλύονται σε κοφτερά γυαλιά, οι τρίπλεξ συγκρατούν τα θραύσματα και οι tempered θρυμματίζονται σε ακίνδυνα για τη σωματική ακεραιότητα κομμάτια.

Laminated glazing

Laminated glazing are often call as security glazing, as the glass has the capacity to be held in place, in the event of breaking, thanks to the interlayer, attributing safety characteristics to them.

Securit or Tempered glass

Tempered glass is a type of safety glass that is 5-10 times stronger than regular glass, due to its making process that involves extreme heating and rapid cooling. When tempered glass breaks, it shatters into little pebbles without any dangerous sharp edges.

Ballistic and bulletproof glass

Ballistic and bulletproof glasses fall under the laminated glazing category. The glass panel is created of layers of laminated glass and a special type of interlayers between them, in a way that the glazing becomes resistant to penetration by projectiles. Bulletproof glass is categorized according to its resistance against bullet attack, under the European standard EN 1063.

Window mechanisms

Windows carry European mechanisms with multiple locking system along the sash’s perimeter, so as to provide high level of protection. Sliding systems have lift and slide mechanisms, increasing security and watertightness, when in closed position.

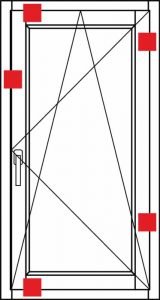

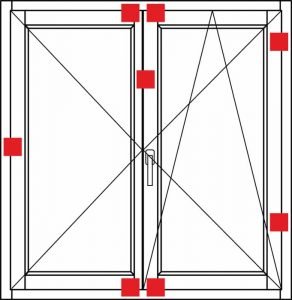

Locking points along the sashes perimeter

Locking fittings

Tilt-turn fittings

Handle for opening 2nd sash in double-sash window/terrace door

Hidden hinge

Moreover, special hardware (i.e. alarm fittings), handles or hinges’ covers may be applied, to fit your custom needs.